This article is based on Bart Baekelandt’s brilliant talk at the Computer Vision Summit in London. Pro and Pro+ members can enjoy the complete recording here. For more exclusive content, head to your membership dashboard.

Hi, I’m Bart Baekelandt, Head of Product Management at Robovision.

Today, we’re going to talk about the lessons we’ve learned over the last 15 years of applying AI to robots and machines at scale in the real world.

Robovision’s journey: From flawed to fantastic

First, let’s look at what these machines were like in the past.

15 years ago, our machine was very basic with extremely rudimentary computer vision capabilities. It used classical machine vision techniques and could only handle very basic tasks like recognizing a hand. Everything was hard-coded, so if you needed the machine to recognize something new, you’d have to recode the entire application. It was expensive and required highly skilled personnel.

Nowadays, we don’t have just one machine – we have entire populations of machines, with advanced recognition capabilities. There’s a continuous process of training AI models and applying them to production so the machines can tackle the problem at hand.

For example, there are machines that can take a seedling from a conveyor belt and plant it in a tray. We have entire fleets of these specialized machines. One day they’re trained to handle one type of seedling, and the next day they’re retrained to perform optimally for a different variety of plant.

So yeah, a lot has happened in 15 years. We’ve gone from initially failing to scale AI, to figuring out how to apply AI at scale with minimal support from our side. As of today, we’ve produced over 1000 machines with game-changing industrial applications

Let’s dive into a few of the key lessons we’ve picked up along the way.

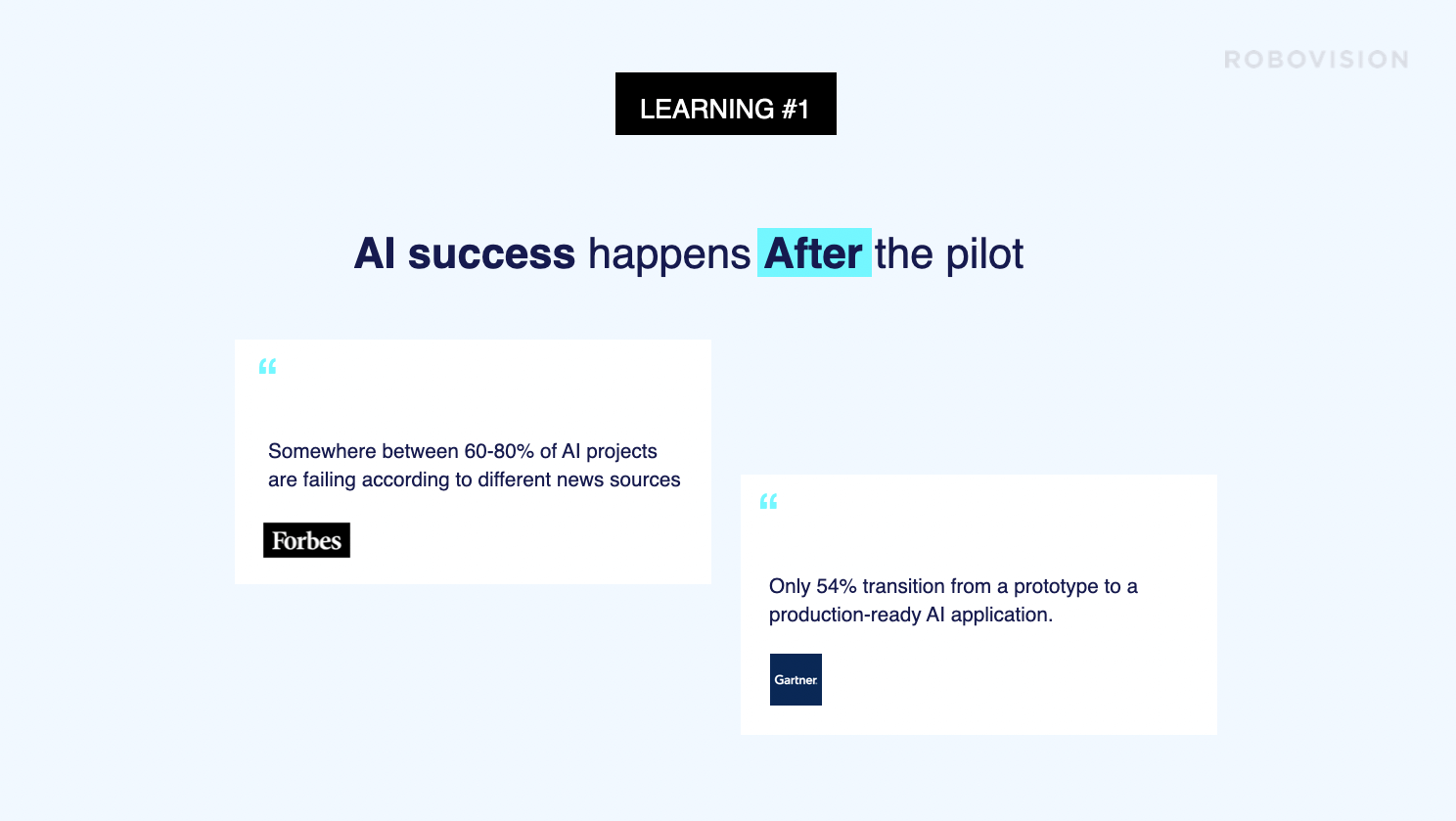

Lesson one: AI success happens after the pilot

The first lesson is that AI success happens after the pilot phase. We learned this lesson the hard way in the initial stages of applying AI, around 2012.

Let me share a quick anecdote. When we were working on the machine that takes seedlings from a conveyor belt and plants them in trays, we spent a lot of time applying AI and building the algorithm to recognize the right breaking point on each seedling and plant it properly.

Eventually, we nailed it – the algorithm worked perfectly. The machine builder who integrated it was happy, and the customer growing the seedlings was delighted because everything was functioning as intended.

However, the congratulations were short-lived. Within two weeks, we got a call – the system wasn’t picking the seedlings well anymore. What had happened? They were now trying to handle a different seedling variety, and the images looked just different enough that our AI model struggled. The robot started missing the plants entirely or planting them upside down.

We got new image data from the customer’s operations and retrained the model. Great, it worked again! But sure enough, two weeks later, we got another call reporting the same problem all over again.

This highlighted a key problem. The machine builder wanted to sell to many customers, but we couldn’t feasibly support each one by perpetually retraining models on their unique data. That approach doesn’t scale.

That painful lesson was the genesis of our products. We realized the end customers needed to be able to continuously retrain the models themselves without our assistance. So, we developed tooling for them to capture new data, convert it to retrained models, deploy those models to the machines, and interface with the machines for inference.

Our product philosophy stems directly from those harsh real-world lessons about what’s required to successfully scale AI in real-world production.

Lesson two: It’s about getting the odd couple to work together

When you’re creating working AI solutions at scale, there typically are two types of people involved. They’re your classic “odd couple,” but they need to be able to collaborate effectively.

On one hand, you have the data scientists – they generally have advanced degrees like Masters in Engineering or even PhDs. Data scientists are driven by innovation. They live to solve complex problems and find solutions to new challenges.

Once they’ve cracked the core issue, however, they tend to lose interest. They want to move on to the next big innovation, rather than focusing on continuous improvement cycles or incremental optimizations

On the other hand, you have the machine operators who run the manufacturing systems and processes where AI gets applied at scale – whether that’s a factory, greenhouse, or another facility.

The machine operators have intricate knowledge of the products being handled by the machines. If you’re deploying AI to handle seedlings, for example, no one understands the nuances, variations, and defects of those plants better than the operator.

Source link

lol