//php echo do_shortcode(‘[responsivevoice_button voice=”US English Male” buttontext=”Listen to Post”]’) ?>

Engineers designing power systems must meet several specifications for input voltage ranges and transients, load requirements, EMI, environmental conditions, heat management, and reliability. Military applications are the most demanding and require special filtering and protection circuits to ensure safe operation under extreme conditions. The following article describes how these challenges can be solved and shows some typical power solutions.

Today almost all power converters use topologies switching at several hundred kHz frequencies, generating a certain amount of conducted and radiated high-frequency noise. A simple PI filter solution integrated into a power converter may be sufficient for very low power levels of a few Watts. Designing an EMI filter for a system drawing several tens or hundreds of Watts can become a real challenge and requires a sound knowledge of HF design and proper layout. Each converter topology generates a different spectrum of high-frequency noise, varying also by the amount of power drawn by the application, and the filter must be designed for all operation conditions.

Before a filter solution finally meets the specifications, it can take several trials and tests in an expensive approval lab, specialized in MIL standards. This time-consuming process adds a significant amount of money to the overall design cost of a new project, which must be amortized over the usually lower quantities in MIL applications.

Space and weight in military equipment are often limited as systems are packed with complex electronics and sensors. A highly sensitive measurement or communication device may work near a power converter and no interference is allowed between different systems. Therefore, EMI specifications for MIL applications are more stringent than in other markets making the filter design even more complex.

Another challenge is the extreme environmental conditions including high mechanical stress caused by shock and vibration. Magnetics and capacitors needed for EMI filters are bulky components and special means are needed to avoid any damage of components or solder connections by high shock and vibration.

Why spend a lot of money and weeks of valuable engineering resources when off the shelf filter solutions are available, meet all these requirements, and are tailored to a wide range of DC/DC converters? The MCF-028 front-end filter family from P-DUKE was designed to cover power ranges from 45W up to 250W in typical 28V defense applications. Their filter behavior is compliant with hundreds of DC/DC converters and by following the recommended PCB layouts, it is very easy to design a system that passes the EMI tests the first time without the need for further redesigns.

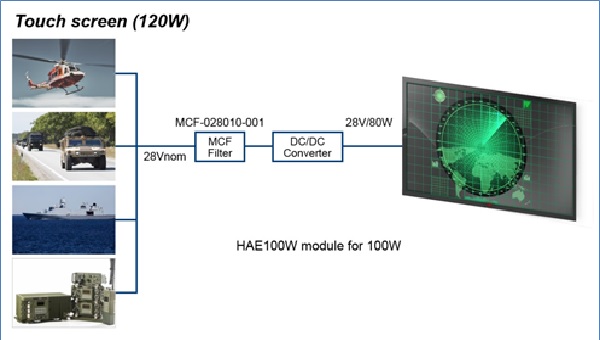

An example is the 80W power solution for a touch screen, which requires a regulated 28V supply voltage to be generated from the unregulated voltage of MIL vehicles. It uses the MCF-028010-001 filter rated for up to 10A and a 100W converter from the HAE100 family (figure 1).

In an application note, P-DUKE provides a list of all necessary external components and a recommended PCB layout. When following this guide a design passing all tests can be made even without a deep knowledge of HF and EMI filter technology. Figure 2 shows the EMI plot of this solution.

MCF-028010-001 combined with HAE100-24S28W at Vin (nom) and full load.

Another challenge in MIL applications is the wide range of the input voltages including heavy transients and spikes. Following table shows the summary of different standards:

According to MIL-STD-1275 the 28V nominal voltage can drop to 16V during the cranking of an engine and even 12V for one second during initial engagement of a system.

On the other side, the system must also be able to handle these high energy transients of up to 100V/50ms or 80V/100ms and spikes up to ±250V/70µs or ±600V/10µs.

Technically it would be possible to design a DC/DC converter working over this wide input range of 12 – 100V but the solution would be bigger and less efficient than a significantly smaller filter and converter combination tailored to these specific needs.

The converter must be able to work at low input voltages and all converters offered by P-DUKE for these applications can handle input voltages down to 9V and are designed to work with input voltages up to 36V continuous and 50V for one second.

An active circuit already integrated in P-DUKE’s MCF-028 front ends clamps the 100V/50ms and 80V/100ms transients to only 40 or 46V, with no problem for the P-DUKE converters with their input transient capability of 50V for one second. Figure 3 shows the input transients applied to a MCF-028010 and the output voltage clamped at 46V.

The very short ±250V/70µs or ±600V/10µs spikes are suppressed by additional components inside the MCF028 and in combination with a P-DUKE converter all these transient specs are met.

The extreme flexibility of P-DUKE’s power component offering is shown when looking at some more application examples:

Figure 4 is the block diagram of a complete onboard computer system including the previously mentioned touch screen and a typical computer using ruggedized CPU, memory, and interface components.

When more power is needed, the MCF-028015 can handle currents up to 15A and support downstream converters for loads up to 250W. A good example is a vehicle-mounted SAT com system (figure 5). When the vehicle drives in rough terrain, powerful motors are needed to continuously reposition the SAT dish.

MIL equipment not only has to work under very harsh environmental conditions, but it also must be fault tolerant to many operating or installation errors. A reverse polarity connection to a battery can damage the complete system. Switching on many loads at the same time can generate high inrush currents and trip system-relevant fuses. P-DUKE considered these handling errors when designing the MCF Frontends and has included an active inrush current limiter and reverse polarity protection as well as under and overvoltage, short current, and over-temperature protection. A remote on/off function allows switching the outputs of each module on and off, enabling a controlled ramp-up or ramp-down of converters in a larger array.

Figure 6 describes a complex mobile network link solution for the communication between UAVs, ground vehicles, ground and portable stations, and a central HUB. Different Combinations of P-DUKE’s MCF028 front ends and DC/DC converter families made designs for the various power needs quick and easy. Even when switching on various systems connected to the same source in a ground node group, the inrush current limiting guarantees that no fuse will trip. The EMI performance of the filters makes sure that noise from a converter will not be coupled into the communication network disturbing mission-critical communication.

P-DUKE’s product range for the MIL market does include modules with single and dual output voltages and voltages going beyond the standard offering of other suppliers. For the redesign of a surveillance system, a customer wanted to use PTZ cameras with high-power LEDs for long-distance night sight, each requiring almost 50W of power. Installation in the field must be quick and easy with one cable carrying power and signal. A power over Ethernet solution was needed but the typical solutions available at that time in the MIL market did not allow bringing 50W to each camera over the thin cable. By using the PoE++ (IEEE 802.3bt, 50 – 57V supply voltage) specification and a standard P-DUKE 100W module with its 48V nominal output trimmed up by 10% to 52.8V, the challenge was solved.

The surveillance control system needed a regulated 28V/40W supply. Easy to achieve with a RED60W module as the 24V nominal output can be trimmed up by +20%, quite unusual for a standard DC/DC converter module.

One 250W MCF028 can power up to 4 cameras and there is still enough power for the surveillance system (figure 7).

The harsh environmental conditions of MIL applications can become a major challenge when designing power solutions. The systems must work reliably over wide temperature ranges and withstand high shock and vibration stress.

Engineers designing their power converters and filters face the challenge that standard magnetics and capacitors are large and bulky and therefore sensitive to shock and vibration. P-DUKE modules use special flat and lightweight components and together with silicone potting mechanical stress is reduced to a minimum. Therefore, all modules meet MIL-STD-810F for shock and vibration.

Another big advantage of using a modular approach and these small components is a significant size and weight reduction compared to any discrete design. The complete weight of all modules used in the example of Figure 5 is only 52g for the portable and 185g for the powerful base station version.

It is often mounted into a sealed housing to protect military electronics against water, humidity, and aggressive atmospheres. Conduction cooling can be realized by attaching the baseplate or top cover of the modules to the hermetically sealed chassis of the system (figure 8). This construction offers ideal heat management options, can withstand very high shock vibration stress, and does not need unreliable fans.

This robust construction, designs with the lowest losses and therefore low heat dissipation, the selection of highly reliable components in combination with a production process meeting high-quality standards and 16 hours of burn-in of every product make sure that the components will work reliably in these demanding MIL applications. This table shows the impressive MTBF values (MIL-HDBK-217F, full load) for the MCF028 filter series:

The DC/DC converters shown in the examples achieve similar MTBF values. P-DUKE has a proven record of meeting the extremely demanding reliability requirements in defense and railway applications under extreme environmental conditions. When using this modular approach, a design can be done in a few days or weeks and does not need months of valuable engineering resources.

Source link

lol