Process intelligence has emerged as central to the successful implementation of artificial intelligence. But before any transformation occurs, a deep, company-wide understanding of underlying processes is critical to deploying effective AI solutions.

Client companies unpack Celonis’ approach to process intelligence, APIs and supply chains.

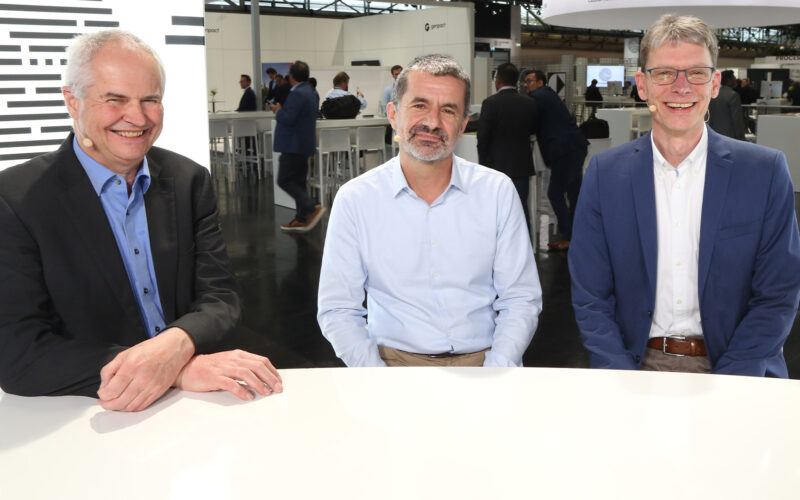

“No process in our branch starts and ends within our company,” said Georg Schukat (pictured, left), managing director of Schukat electronic Vertriebs GmbH. “We were always limited by what we could see and what we could act on. Now, we open it up to the whole process chain. We can look really from the factory down to the customer, with all the steps in between. That’s a potential I see, and that was the reason we wanted to invent on that.”

Schukat, alongside Jörg Frenzel (right), director of operational excellence at Conrad Electronic Group, and Pablo Fernandez (middle), process transformation and innovation director at TD Synnex Corp., spoke with theCUBE Research’s Rob Strechay at Celosphere 24, during an exclusive broadcast on theCUBE, SiliconANGLE Media’s livestreaming studio. They discussed the future of process intelligence evolving to connect all points in a supply chain, creating a more resilient, efficient and responsive network. (* Disclosure below.)

Embracing API evolution for real-time connectivity in process intelligence

As part of this drive for innovation, companies are moving beyond traditional electronic data interchange methods, which often lack flexibility, according to Fernandez. Instead, many are adopting advanced application programming interfaces that provide more granular and real-time data exchange capabilities.

“The interesting part is that realization moment when you realize that [you] cannot do it by yourself, that you need to connect to the others,” Fernandez said. “We have [electronic data interchange] and other systems, but I think these networks broke those boundaries, and then we can go from the beginning to the end. It doesn’t matter how many partners are in the middle.”

Trust and transparency are essential for effective process collaboration. By creating a “virtual private process group” using Celonis software, companies can securely control shared data while providing needed visibility, according to Frenzel. Legal agreements and selective data-sharing protocols further protect each party’s information, building a foundation of trust that makes open communication and continuous improvement possible.

“We get some internal fear or resistance about this thing,” Frenzel said. “But then you can prove very easily that you share the information you want with the people you want. I think that’s a very powerful message. If you think of that, I prefer this much more than people in the organization sending emails with attachments with zero control.”

Here’s the complete video interview, part of SiliconANGLE’s and theCUBE Research’s coverage of Celosphere 24:

(* Disclosure: TheCUBE is a paid media partner for Celosphere 24. Neither Celonis SE, the sponsor of theCUBE’s event coverage, nor other sponsors have editorial control over content on theCUBE or SiliconANGLE.)

Photo: SiliconANGLE

Your vote of support is important to us and it helps us keep the content FREE.

One click below supports our mission to provide free, deep, and relevant content.

Join our community on YouTube

Join the community that includes more than 15,000 #CubeAlumni experts, including Amazon.com CEO Andy Jassy, Dell Technologies founder and CEO Michael Dell, Intel CEO Pat Gelsinger, and many more luminaries and experts.

THANK YOU

Source link

lol