Written in collaboration with Navin Sharma and Joe Pindell, Stardog

Across industries, the impact of post-delivery failure costs (recalls, warranty claims, lost goodwill after delivery) can be enormous. In the food industry, the average cost can be over $10M per event in direct costs. The impact is often multi-dimensional, due to lost sales and brand reputation damages. According to some estimates, the lost sales from post-delivery failures is equivalent to over 2,000 times the average revenue per customer. Inadequate resolutions and slow responsiveness to customers, particularly in high-stakes situations like this, can make them churn to competition, cutting off the oxygen that fuels future growth. Thus, it is no surprise that the cost of poor quality is a significant financial burden to manufacturing companies, and in some cases can cost companies up to 40% of operating costs.

While companies wish they could have more early warning indicators of impending quality issues, usually, companies only get to know after the fact, driven by an uptick in customer complaints that are constantly being monitored by the organization. A typical issue looks like this: over the weekend, the number of customer-reported issues from the field spikes and reports are signaling product quality issues and dissatisfaction with the brand. When it is in effect, a situation like this is indeed a fire drill. Customers no longer simply accept longer lead times for response and demand an elevated standard to deal with such issues.

Developing a New Way to Play with Databricks & Stardog

As most organizations know, quality issues are not usually isolated instances. These are recurring problems that need repeatable solutions and systems to continuously monitor customer feedback, prioritize urgent issues, and drive faster resolution. When hit with a quality issue, companies want to gain a deeper understanding of the scope of the problem, potential secondary impacts, gain a better understanding of underlying root causes upstream in manufacturing processes and supply chain, to avoid costly issues like this in the future.

This requires incorporating all disparate data sources to understand the multiple interconnections between the different data domains and developing the company’s knowledge base and systems. Today, we’ll highlight the power of using Stardog’s Generative AI powered by a knowledge graph with Databricks to help manufacturing organizations to conduct quality event forensics to quickly identify problems and improve customer outcomes.

Stardog Voicebox can identify and link data associated with business objects like plants, suppliers, production processes, logistics, product families, SKUs etc. This linking capability provides better and faster decisions for manufacturing and supply chain use cases. Additionally, the Stardog platform integrates with Databricks via Partner Connect and leverages Databricks to process data at scale.

To explain how Databricks and Stardog will help companies build an end-to-end capability to better manage quality incidents, we will take an example of a beer distributor supplying beer to various stadiums during sporting events. At a high profile game, the company starts receiving reports that a large number of fans are finding the beer to be “flat” – setting a series of events in motion.

Execute Rapid Quality Event Forensics

When it comes to quality issues, time is not your friend, and neither is siloed and disconnected data. As a product quality SME, you want to triage the situation as fast as possible in order to deploy the right resources to address the issue at hand, ensuring critical quality concerns receive immediate attention.

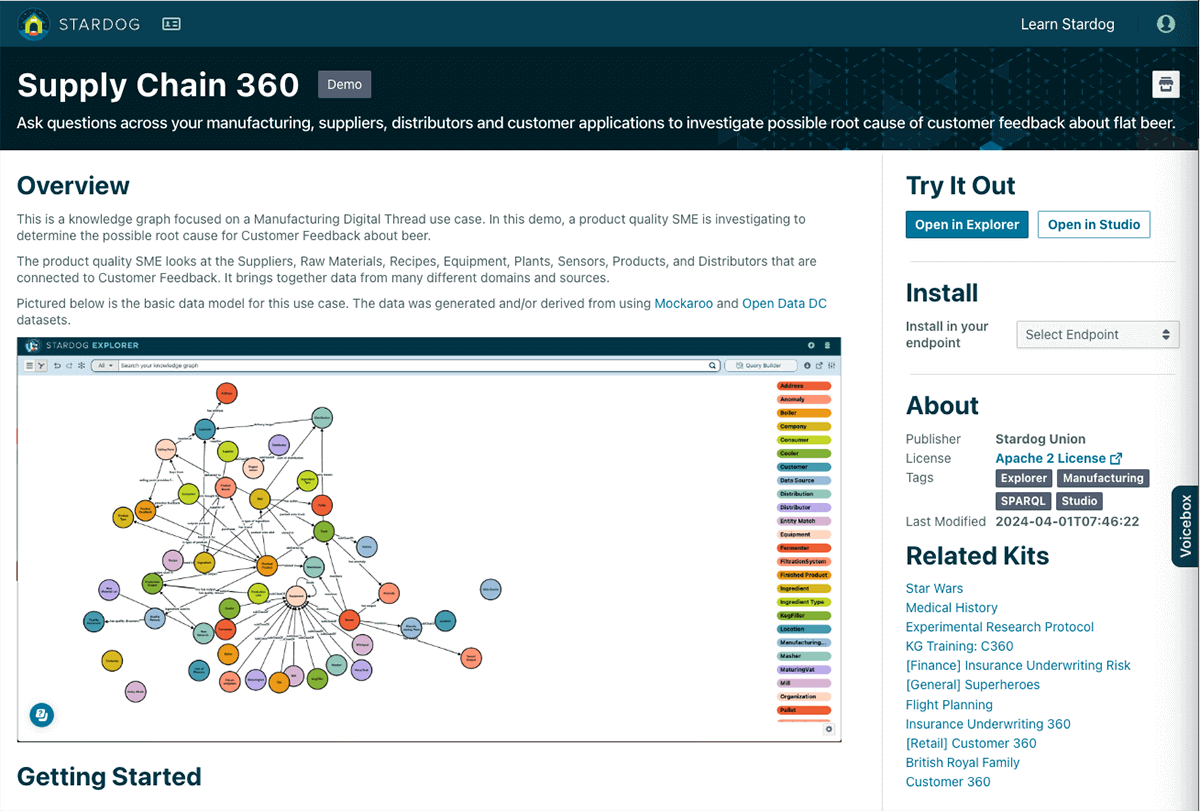

As a product quality SME, we would start with the negative feedback to understand what the feedback is, what it’s about, and where it came from. This would require visibility across Product Feedback, Finished Products, Selling Points, Stadiums, Distributors, Trucks, Sensors, Pallets, and Suppliers. This brings together data from many different domains and sources.

Stardog is a knowledge graph platform that allows businesses to connect and query data in a flexible and interconnected way. This makes it ideal for customer and product support, as it allows us to quickly and easily find the information we need to research these customer issues. This makes it easy for other customer support agents to find the information they need to resolve customer issues, in natural language, even if they are not familiar with the underlying data structure.

A unique feature of a Stardog knowledge graph is the ability to define rules that apply to the data at query time. Reasoning enables Stardog’s Inference Engine to associate related information to infer new connections. These rules do not create any new data but allow you to interact with them as if they were actual data. The Anomaly concept below is something that you won’t find defined or stored explicitly anywhere in the data. It is an implied output when the defined conditions of the rule are met.

Let’s look at the rule definition below. As you can see, if any truck has a temperature sensor with any sensor output equal to or greater than 50 degrees Fahrenheit, then Stardog’s Inference Engine infers that the truck has an anomaly associated with it.

These data shortcuts become incredibly useful in helping the product-quality SMEs in their interrogation. For example, reasoning infers that Truck 002 has 11 anomalies because it has a temperature sensor that has 11 outputs equal to or greater than 50 degrees Fahrenheit. With this discovery, the product quality SME can see that the temperature difference on the truck contributed to the flat beer. While this is may be a good discovery, it opens the door to even more important questions to understand the full extent of the problem.

Estimate Blast Radius

An earthquake is usually accompanied by a wave of aftershocks, and this is also true in the case of product quality issues. Estimating the potential scope of a quality issue involves assessing its potential impact on other batches of the same product, similar products or in this case related venues. Since we’ve traced the problem down to a specific vehicle, we need to assess the potential downstream impact that might affect other customers.

Let’s dig in a little further on Truck 002 and see if it’s headed anywhere else. A quick conversation with Stardog Voicebox shows us the Truck 002 is scheduled for two delivery locations.

Since we know from our troubleshooting that the original complaints came from Wrigley Field, we should turn our attention to alerting the personnel at Indianapolis Motor Speedway about the flat beer. At a minimum, they should inspect the product before serving to prevent additional negative reports. In the event they have a shortage, then we might be able to find an alternate truck with the same product, or worst case, offer customers a coupon.

By evaluating all potentially related circumstances, businesses can estimate the blast radius of a product issue and proactively make decisions to address it. This may involve implementing mitigation strategies such as product recalls, software updates, or manufacturing process adjustments to minimize the impact on customers.

Traceability to Production and Supply Chain Issues

Tracing back to production and supply chain issues is a critical step in resolving problems. By identifying the root causes of issues and taking corrective actions, companies can develop more effective solutions and prevent recurring issues. This may involve identifying with suppliers to improve quality, finding alternative sources of supply, or making changes to production processes.

Supply chain visibility is crucial for any manufacturing organization seeking to improve experiences and outcomes, but less than 6% of organizations are there today. The Databricks Data Intelligence Platform built on the Lakehouse architecture, coupled with Stardog as a semantic layer – enables companies to build a more connected view of their data and the relationships between them. This can be an immense advantage for dealing with supply chain challenges, such as quality event forensics, that demands a comprehensive, connected view across datasets – which ultimately enables manufacturing companies to drive data-driven decisions.

Get Started Today!

Unlock the potential of Stardog today by visiting the Databricks Partner Connect website. Follow the step-by-step instructions provided in the Stardog documentation to connect Stardog with Databricks. Once connected, you will gain access to the Supply Chain 360 knowledge kit, a comprehensive resource containing everything you need to follow the example above.

Source link

lol